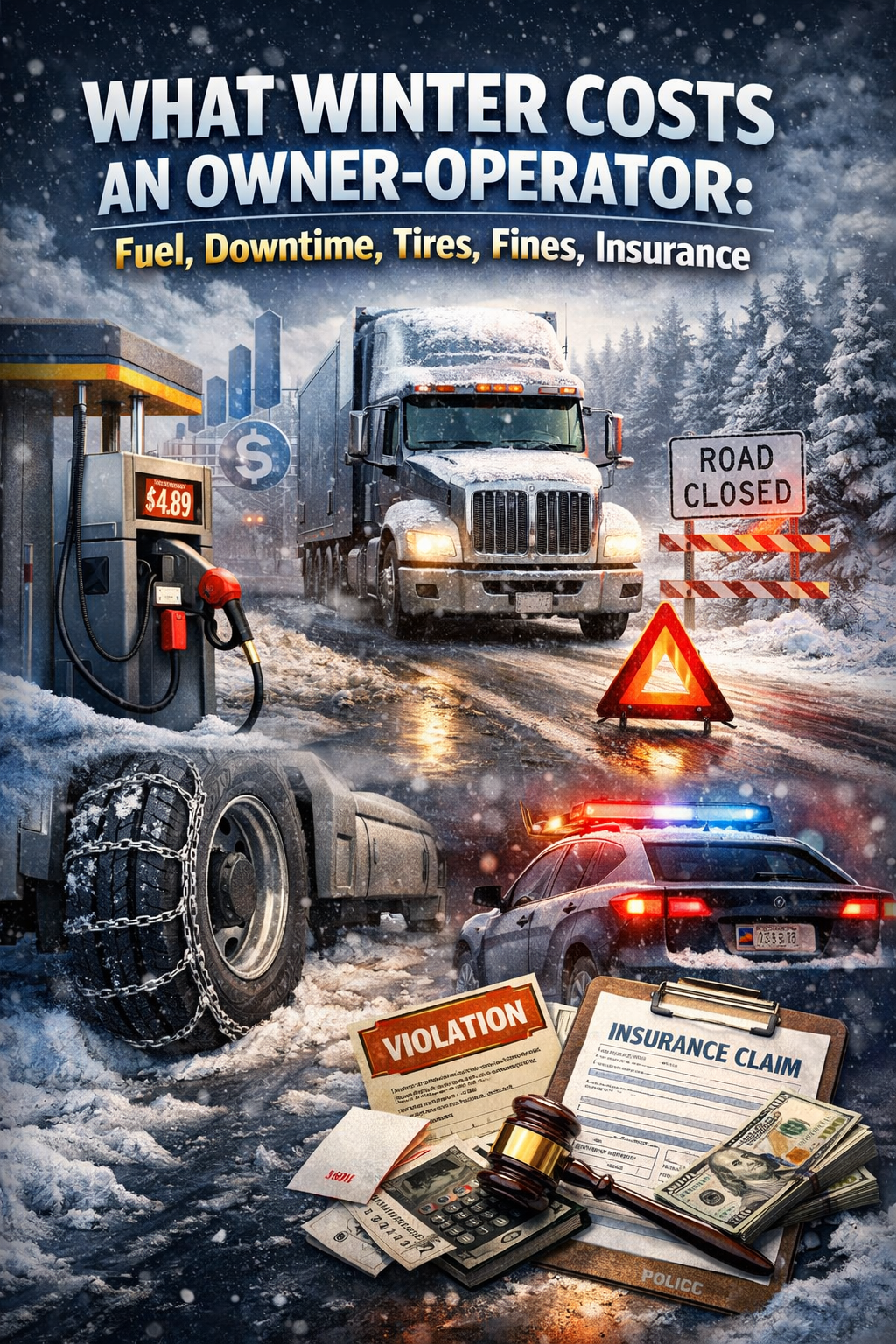

Winter for an owner-operator is not just another calendar season. It’s a real test of financial strength. Driving in the cold exposes layer costs that remain. Fuel, downtime, tires, insurance, and fines that appear where margins are already thin are the many expenses born out of the winter challenge. The winter truck driver is seldom one major expense away from the bottom line but instead experiences multiple smaller, compound winter trucking costs that same the single losses suffered by the operator.

These winter trucking costs form the core of owner-operator winter expenses that are often underestimated before the season starts.

Learning the owner-operator winter costs does not mean being afraid of it or shunning it for one or another reason. It is introduced as a result of fear, recklessness, and lack of control. Winter road conditions, temperature deviations, and operational shutdowns reshape the entire picture of the cost of trucking. Drivers who do not adjust financially easily find out that winter miles look productive on paper but actually they generate a lot less net income than expected.

Winter road conditions play a central role in increased fuel use, downtime exposure, and maintenance stress.

The main purpose of this article is to show the owner-operator how much winter really costs, focusing on fuel, downtime, tires, fines, insurance, and the hidden expenses that come with cold weather trucking.

Winter Fuel Costs: The Invisible Profit Assassin

One of the first signs a trucker sees of changing expenses is winter fuel costs, however, they are often underestimated. Increased fuel consumption is usually not a consequence of driving more miles. In winter, the fuel naturally rises despite the flat productivity.

Increased fuel consumption is one of the earliest and most consistent winter trucking costs.

The temperature itself is what is affecting the fuel. One of the biggest contributors to the reduce of efficiency is the time the engine takes in order to warm up, idling time is higher, and diesel in low temperatures behaves differently. The winter blend gives you higher mpg during the warm months but it was designed specifically to help keep things free flowing. Powering up more and idling more often during stops, and operation of auxiliary heaters are additional reasons for elevated freight charges.

In stop-and-go winter traffic, fuel efficiency drops further. Snow-covered roads, slush resistance, and lower average speeds increase engine load. Even short urban runs consume more fuel in cold weather than longer highway trips in summer.

Fuel costs in winter rarely scale with miles, making budgeting more complex for owner-operators.

Fuel-Related Winter Cost Drivers

| Factor | Winter Impact | Cost Result |

| Extended idling | Higher engine runtime | Increased fuel consumption |

| Cold starts | Poor combustion efficiency | Extra fuel usage |

| Winter diesel blends | Lower energy density | Reduced MPG |

| Auxiliary heaters | Constant fuel draw | Hidden daily fuel cost |

| Slush & snow resistance | Higher rolling resistance | Increased burn per mile |

How to Calculate Owner Operator Trucking Costs Per Mile

Downtime: The Most Costly Winter Expense

No truck operator really plans for downtime during the winter, but it is a one big hit to their pockets during the winter. Each parked hour translates to lost revenue which every owner-operator would be wise to consider.

Truck downtime winter losses often exceed fuel expenses over the full season.

Driving in winter weather is not only an issue with accidents, but also an issue of slowdowns and road conditions that create problems. Road closures, weather chain controls, and traffic incidents together add to downtime. In winter, when the truck is fully operating, the freight schedules still collapse.

When it comes to mechanical failure, the rental truck is more often out this winter. Cold starts stress batteries, starters, and electrical systems. Broken air lines, sensor failures, and fuel system problems are problems related to cold weather trucking.

Semi-truck winter maintenance issues frequently surface during unplanned shutdowns.

Common Winter Downtime Triggers

- Weather-related road closures

- Chain control delays

- Cold-start mechanical failures

- Battery and air system issues

- Missed delivery windows

- Lack of winter-safe parking

Many times downtime appears to be their secret enemy because it doesn’t show on a direct line-item. With lost miles, hotel costs, parking fees, missed reloads, and extended layovers directly targeted profits of owner-operators for many winters.

Semi-Truck Winter Maintenance: Repairs Add Up Fast

Truck repair costs winter are mostly small on their own, but they build up fast. Cold weather makes some of the components weaker. Rubber gets hard, metals get small, and oils are not working as before.

Truck repair costs winter are rarely catastrophic alone but accumulate rapidly over time.

Semi-truck winter maintenance makes more frequent inspections, replacing weather-sensitive parts, and preventive repairs that cannot be delayed. Heater systems, defrosters, air dryers, batteries, and fuel lines all need care.

Heavy haul winter operations experience accelerated wear compared to standard freight.

Winter Maintenance Cost Accumulation

| Component | Winter Stress Factor | Cost Risk |

| Batteries | Cold cranking load | Replacement & downtime |

| Air system | Moisture freezing | Line failures |

| Fuel system | Gelling risk | Emergency service |

| Tires | Reduced flexibility | Accelerated wear |

| Brakes | Slush & corrosion | Shorter lifespan |

Winter and Tire Costs: Traction Is Expensive

Winter tire costs are an additional inevitable element in the cold weather trucking business. Tires act differently in low temperatures, and on snowy or icy roads, the demand for traction increases.

Winter tire costs extend beyond purchase and directly affect operational reliability.

Cold rubber has less flexibility. Tire pressures fluctuate more. Chains damage sidewalls and treads. Braking on icy roads causes irregular wear.

Winter tire costs are closely tied to safety, downtime prevention, and insurance risk.

Fines and Compliance Costs in Winter

Trucking fines winter season are often misunderstood. They emerge from chain laws, speed restrictions, mandatory equipment requirements, and emergency parking rules.

Trucking fines winter penalties increase due to temporary weather-based regulations.

Compliance mistakes in winter directly impact future operator insurance costs.

Insurance in Low-Weather Exposure

Insurance is one of the least visible winter expenses. Winter driving insurance exposure affects premiums even without major claims.

Operator insurance costs tend to rise after winter claim history is reviewed.

Cold Weather Transport Tips Pile Up

Not only in terms of fuel, downtime, tires, fines, and insurance, winter brings persistent additional truck driver expenses.

Seasonal trucking costs often come from overlooked operational necessities.

Often Overlooked Winter Expenses

- Hotel stays during closures

- Paid winter parking

- Emergency supplies

- Fuel additives

- Washer fluid & antifreeze

- Towing and recovery gaps

Managing Winter Trucking Costs as an Owner-Operator

Managing winter trucking costs starts with accepting seasonal volatility as part of the business.

Owner-operator profits winter performance depends more on planning than mileage.

Controlling Your 5 Biggest Expenses as an Owner-Operator

Winter Season and Owner-Operator Profit Truth

The cost associated with winter trucking is not a single item. It is a whole interconnected system of costs brought about by cold weather trucking factors.

For owner-operators, winter is not about avoiding work — it is about controlling exposure, protecting margins, and surviving the season with equipment, license, and finances intact.

FAQ

1. How do LSI keywords trucking help explain winter costs for owner-operators?

LSI keywords trucking predominantly carry the function of categorizing winter-related costs into larger groups so that one does not perceive them as separate expenses. For instance, when fuel, downtime, maintenance, and insurance are viewed together rather than separately and through LSI keywords, it is easier for owner-operators to conclude that winter trucking costs -sit well- beside one another and the origin of them is from more than one source.

2. Why are bigrams trucking winter useful when analyzing seasonal expenses?

Bigrams trucking winter are a reflection of the fact that costs behave specifically in cold weather rather than in interference of the normal truck operations. The usage of bigrams trucking winter empowers owner-operators to separate costs that are incurred all year round, from costs that are incurred only in winter like extra fuel consumption, weather downtime, and additional maintenance stress from ice roads.

3. What does proper winter preparation trucking actually include?

Winter preparation trucking is not just about the basic vehicle checkups. This refers to pipeline planning for fuel usage, downtime budgeting, tires and brake systems prepping for cold, winter local regulation understanding, and risk on the insurance side. Financial discipline is equally significant as the correct installation of machines in winter operations.

4. Can winter preparation reduce owner-operator winter expenses?

Yes. Though winter preparation trucking cannot get rid of all seasonal costs, it greatly reduces the unexpected ones. Scheme of fuel consumption, taking care of winter-safe parking, giving schedules for preventive maintenance, and weather-related delays will help to stabilize owner-operator winter costs and protect their profit margin.

5. Why do winter trucking costs feel higher even when driving fewer miles?

The rise in winter trucking costs is due to expenses not being proportional to miles. Cold starts idling, going slow, downtime, bad weather related maintenance costs raise the cost per mile altogether. Recognizing such a tendency through winter preparation trucking and the right cost analysis helps owner-operators not to overestimate their winter profits.