In the trucking business, transportation often symbolizes growth. The more miles traveled, the more goods delivered, the more respect for schedules, and the better the overall picture of the company.Some companies might view this as a logical pattern and stopping jobs as a failure: lost time, loss of money, and damaged credibility.

But being in the field depicts otherwise.

For instance, traffic-control devices were not always the ones that let the worst changes in the weather that seeing them would, due to age.

Weather disruptions force companies to rethink traditional assumptions about productivity and reveal how decision making under pressure directly affects long-term outcomes.

The truly maneuverable carriers have not survived the terrible weather just because they striven harder. It was due to the fact that they accepted the obvious and logically sound decision of not doing anything at this moment. Smart shutdowns are not about fear or weakness. It is a decision that is made on the bases of risk management, safety measures, and operational stability in the long run.

This approach reflects modern disaster preparedness, where stopping operations is treated as a preventive business tool rather than a reactive failure.

This article looks at three instances that are true examples o shutdown strategies during hurricanes that protected properties, minimized losses, and ultimately saved the business the necessity of that.

Why Bad Weather Should Be Considered a Business Threat — Not Only a Driving Challenge

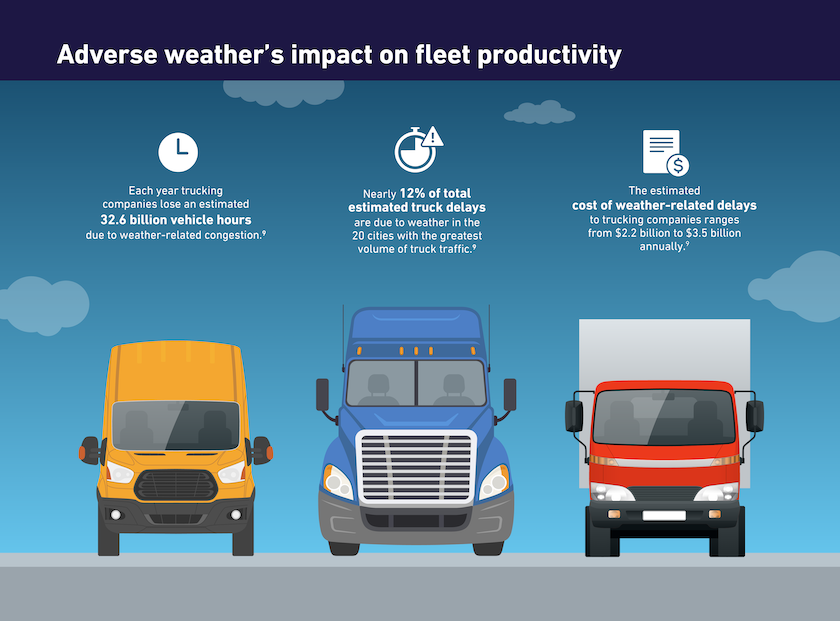

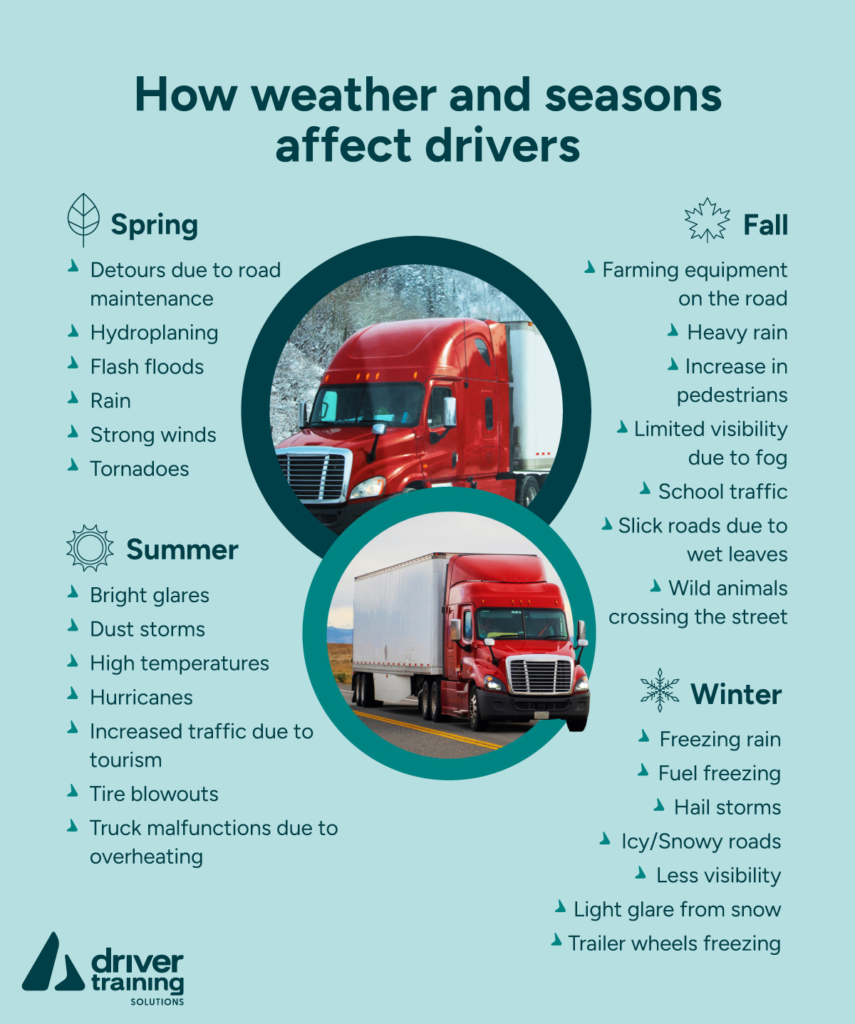

Weather breakdowns are no longer mad or random. The latest news talks about ice storms, floods, reverse winds, snow, and unexpected temperature changes. These events are happening with high intensity rates. Now, for trucking operations, the weather is no longer the only driving condition — it is a critical business variable.

Weather disruptions increasingly influence scheduling, insurance exposure, and the financial stability of fleets across all regions.

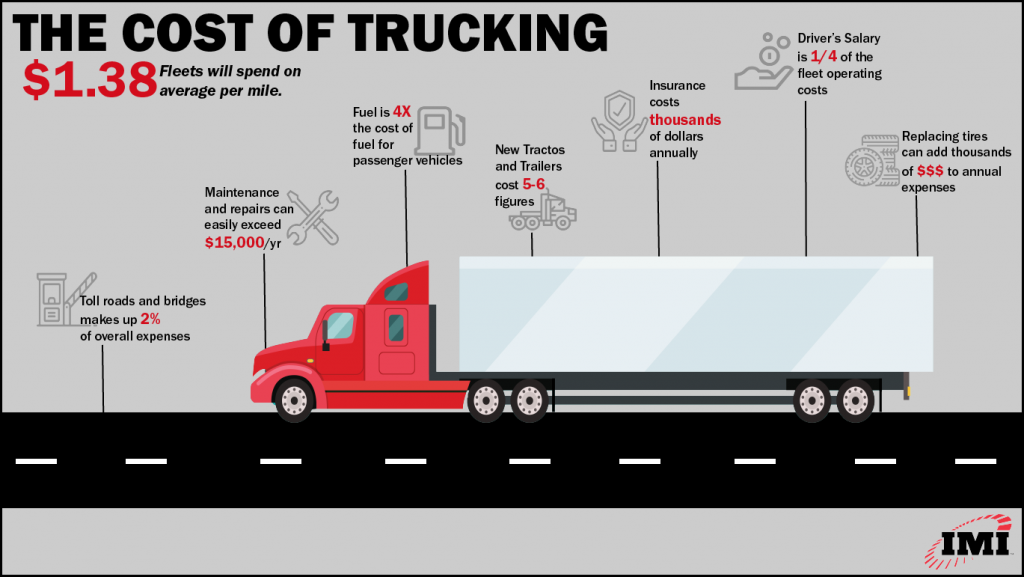

Severe weather has a direct effect on:

- driver safety and fatigue

- equipment performance and maintenance period

- insurance exposure and liability

- customer commitments and service-level agreements

- profitability during high-risk periods

Severe weather directly impacts driver safety, visibility, and vehicle control, increasing the risk of accidents and delays during snow, ice, and heavy rain. Advanced preparation and safety measures are critical to mitigate these risks in trucking operations. Labworks USA

Neglecting weather risk is not a valid way to keep productivity. It only increases financial losses.

Effective decision making during adverse conditions helps prevent cascading failures and protects long-term company savings. A smart shutdown sees the weather condition not just as a tactical threat but also as a major issue in business operations that has to be handled through a systematic approach.

Winter Trucking Safety: Expert Tips for Driving in Snow, Sleet, and Black Ice

Case Study 1: Ice Storm Shutdown That Was a Complete Money Maker

The Situation

A small regional carrier located in the Midwest was a mixed fleet and had gotten alerts about the incoming ice storm. The storm was mainly a concern because of the ice freezing overnight on the major interstates and the feeder routes. At the time of this warning, the roads were still open, and the visibility was okay.

Early warning signals allowed leadership to apply structured decision making instead of reacting after damage occurred.

Some carriers made a dogged decision to fly on, trying to beat the cyclone that was now set against them.

The Decision

Waiting for the formal announcement of the road closures wasn’t necessary. The dispatch, on its own, initiated the emergency protocol and implemented the scheduled shutdown six hours before the cyclone would strike its peak. The trucks were detached to the secure parking, the freight was secured, and the drivers got a paid leave. The clients were informed immediately.

This proactive move aligned with disaster preparedness principles and prioritized asset protection over short-term revenue.

The decision was made two hours before the weather became dangerous.

The Outcome

Operations took a break only for less than 24 hours. In that time frame, several carriers traveling the same routes reported jackknifed vehicles, ruined trailers, and drivers who got stuck.

The shutdown directly contributed to successful outcomes by avoiding accidents and preserving operational capacity.

This carrier was on the route again as soon as roads were opened — and without a single piece of equipment failure, no cargo claim, and no driver incident.

Financial Impact Comparison

| Impact Area | Continued Operation | Smart Shutdown |

| Accident repairs | High | None |

| Cargo claims | Moderate–High | Zero |

| Insurance exposure | Premium increase | No impact |

| Driver availability | Reduced | Fully intact |

| Net result | Financial loss | Company savings |

Key takeaway: A succinct suspension of operations avoided financial losses and created additional long-term business benefits.

Case Study 2: Wind Event Shutdown That Kept the Structures Forever

The Situation

A long-distance-haul carrier operating at the edge of the plains faced wind conditions of more than what is permissible for single-axle vehicles. The unloaded and light-loaded trailers were particularly at risk, especially on certain bridge crossings and elevated highways that are more vulnerable to high winds.

Weather disruptions in open terrain magnify risk and leave little margin for correction once conditions deteriorate. Rollovers due to wind had been the reason reported already in nearby counties.

The Decision

The all-empty and light-load movements through the impacted area are run which helped transportation management. Instead of going onto secondary roads which would have increased exposure, the company managed to stop all operations in the risk area.

This strategic shutdown reduced exposure and played a critical role in minimizing downtime after the event. Some deliveries were delayed instead of pushing the unsafe transport through.

The Outcome

The standstill lasted one day. During the period, several local carriers had rollover accidents and road closures. Even this fleet didn’t have trouble and once the wind speed was ok, services started normally. Avoiding equipment damage resulted in direct company savings and preserved driver availability.

Key takeaway: Managing risk through strategic shutdowns allows better access to critical infrastructures and fosters faster rehabilitation of operations.

Case Study 3: Flood Shutdown That Stood Guard for Trust

The Situation

A company transporting industrial goods had forewarnings of impending water that would serve as a natural barricade to shipping products to the customer. The customer’s space was forecasted to get submerged within a few hours. Flood-related weather disruptions pose compound risks to drivers, equipment, and delivery timelines.

Competitors tried partial deliveries or alternative routes with the risk of flooding.

The Decision

The company announced the complete closure of flood-affected roads before the event took place. The freight was retained at the upstream terminals, and the customers were informed about the priority of safety, asset protection, and realistic timelines of recovery.

Clear decision making and early communication prevented confusion and reduced reputational risk.

The Outcome

The floods arrived as had been announced. No trucks ended up being marooned, no equipment was left behind, and no drivers were in any danger. The customers highly acknowledged the integrity and professionalism displayed. This approach delivered successful outcomes by preserving trust and ensuring operational continuity.

Operational Impact Comparison

| Metric | Without Shutdown | With Shutdown |

| Equipment loss risk | High | Zero |

| Driver incidents | Likely | None |

| Customer disputes | High | Minimal |

| Downtime | Extended | Controlled |

| Contract stability | At risk | Preserved |

Key takeaway: Preventing damage while building trust by early communication becomes a success that exceeds immediate revenues.

How to Recognize a Shutdown as “Smart” and Not Simply Reactive

Simply shutting down does not count as a choice by itself. A smart shutdown makes the proper decision through the use of proven processes:

- dependable weather sources

- a set of emergency protocols that have already been determined

- the authority of the managers to stop without delay

- communication with drivers and customers ahead of time

- focusing mainly on safety, and protecting the assets, and the business’s continuance.

These elements form the foundation of disaster preparedness within modern trucking operations.

Risk Management and Strategic Shutdowns

Smart shutdowns are an important part of risk management in the trucking sector. When the weather is extreme, the dangers multiply. One misjudgment and day-long downtimes will trigger insurance claims and regulatory risks.

Strategic shutdown planning is designed to limit exposure, reduce financial volatility, and support company savings over time.

Strategic shutdowns help:

- preventing damage before it occurs

- maintaining operations during weather breaks

- protecting drivers, trucks, and cargo

- keeping capital and profitability intact

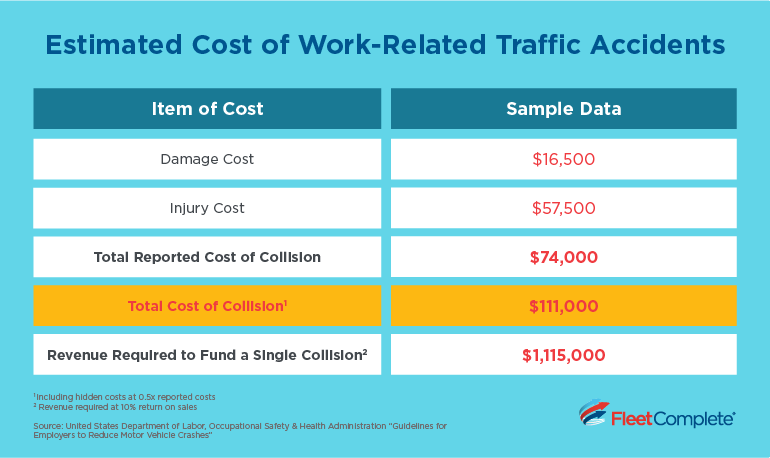

Why “Pushing Through” Oftentimes Will Cost More

A lot of businesses are afraid to implement shutdowns since temporary break appears expensive. But in the long run and with time, unwanted accidents are the far greater cost.

Weather disruptions amplify the cost of errors and quickly erase any perceived gains from continued movement.

Through pushing swiftly past dangerous conditions, carriers often have:

- emergency recoveries

- safety violations

- insurance claims and consequential premium increases

- damaged equipment and prolonged downtime

- loss of customer confidence

Planned downturns reduce exposure and cut recovery time.

Smart Shut-downs and Business Continuity

Business continuity is not just the absence of the activity. The conceptual presence of a business continuity is the ability to withstand disruption and recovery intact.

Strategic shutdowns play a key role in minimizing downtime while preserving operational readiness.

Strategic shutdowns facilitate stability by:

- ensuring driver safety and availability

- protecting assets and infrastructure

- shorter downtime

- restarting quickly once conditions return to normal

In bad weather, survival frequently relies on the knowledge when to hold still.

How Companies Come to the Decision to Shut Down

Making good shutdown decisions is more of a data game than an emotional one. The most prominent signals are:

- weather forecast reliability, not wishful thinking

- trade-off between driver risks and delivery urgency

- asset exposure versus short-term revenue

- the company’s capability to recover operations promptly

Consistent decision making frameworks help fleets respond faster and with fewer long-term consequences. Top fleets understand that shut-downs are alternatives for improved operational efficiency, not a last resort.

Conclusion: The Smartest Decision Sometimes Is Not to Move at All

In trucking, success is, in many cases, calculated by miles and loads. Heavy weather, however, shifts this equation.

These case studies show how smart shutdowns:

- prevented financial losses

- protected drivers and equipment

- minimized downtime

- preserved customer relationships

- saved businesses during extreme weather events

A strategic shutdown is not a sign of weakness. It is a disciplined decision made in the midst of pressure. Companies that integrate shutdown planning into disaster preparedness are better positioned to survive future weather disruptions.

Companies that make weather related disruptions not last through are not the ones that take risks but those that stop early, protect what is valuable, and come back stronger.

FAQ

1. What is a smart shutdown in trucking operations?

A smart shutdown is a planned and data-driven decision to temporarily stop trucking operations during severe weather conditions. Unlike reactive stoppages caused by accidents or road closures, a smart shutdown is initiated in advance to protect drivers, equipment, and freight while preserving business continuity.

2. How can stopping operations in bad weather actually save a trucking business?

Stopping at the right time helps prevent accidents, cargo damage, insurance claims, and the long recovery period. In many cases, a short and controlled shutdown results in lower financial losses than pushing through unsafe weather, making it a practical risk management decision instead of a loss of productivity.

3. Who is responsible for making shutdown decisions in trucking companies?

Shutdown decisions are often made by dispatch managers, safety teams, or fleet leadership with the help of weather data, route risk analysis, and driver safety considerations. Professional decision-making depends on earlier tactics designed to manage emergencies instead of last-minute direction calls.

4. What role do smart shutdowns play in securing driver safety?

Smart shutdowns lower the pressure on drivers to deal with perilous driving situations. By eliminating the anticipation of pushing through the terrible weather, the companies not only keep their drivers away from accidents, fatigue-related mistakes, and the exposure to risky driving conditions.

5. Are smart shutdowns only relevant for large fleets?

No. Smart shutdown strategies are just as important for owner-operators and small carriers. Any operation that relies on safe equipment, dependable drivers, and reliable schedules can capitalize on shutting down earlier to avoid damage and reduce downtime during weather disruptions. LSI keywords: smart shutdown, trucking operations, severe weather, risk management, business continuity, driver safety, fleet decision making, weather disruptions.