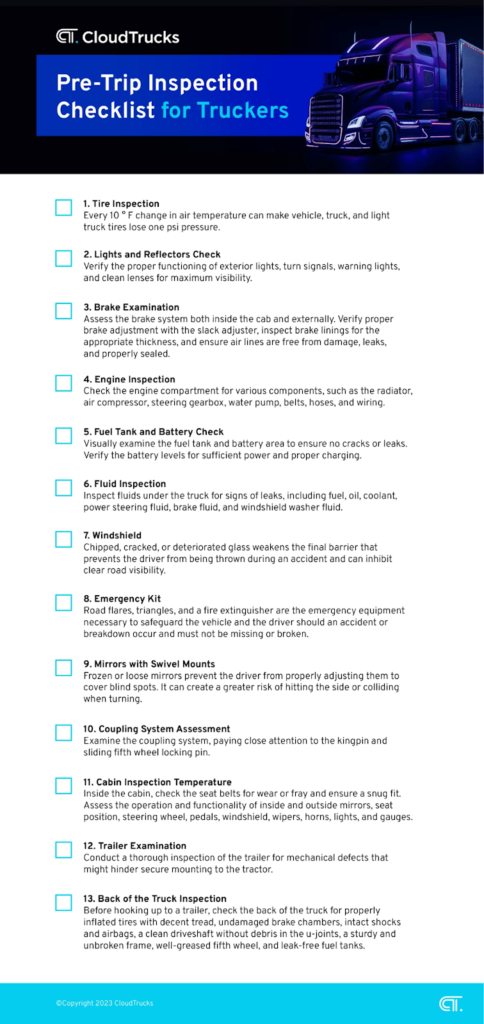

Owner-operators do not regard winter merely as another season; they see it as a practical test of equipment, discipline, and planning. For a general CDL pre-trip inspection, you may just need to check everything in the standard way and get only necessary, or bar code sticker, items to pass a roadside inspection on a clear summer day. However, winter conditions would show up the deficiencies which the basic programs usually fail to notice. Low temperatures, moisture, road salt, and prolonged night driving convert minor oversights into major hazards.

This is where the winter pre-trip inspection turns from a compliance to a survival system. Owner-operators who rely only on the basic checklist usually discover problems that they actually have too late — a complete block of lines, failed brakes, some lights not working, or a blown tire in an unsafe area. A winter-centered strategy that is higher than the full checklist would be less breakdown-involved, safer to drive in winter time, and better for the equipment and total income.

This article makes it easy for owner-operators to know what things to check beyond the simple pre-trip, through covering some realistic winter truck inspection practices that are needed when the state of affairs is harsh.

Winter Operations Maintenance Pre Trip Inspections

Why Winter Pre-Trips Need to Be More Than the Basic Program

Basic CDL pre-trip-troubleshooting is done according to the minimum safety standards and sticky rules that are put forward by the DOT. It guarantees that the truck runs but does not consider the multiple sins or other negative effects of the winter.

During winter, many components of the systems become dysfunctional in ways that are not visible during a quick walk-around. The materials contract, the fluids become thicker while the moisture acts differently along the closed systems. A component that passes inspection at noon may unexpectedly fail after a significant temperature drop occurs overnight.

The winter season shifts technology as follows:

- Fluids thicken, making everything move faster

- Rubber components stiffen and crack

- Air systems build up moisture

- Electrical connections become weak

- Minor leaks become system failures

The beyond pre-trip approach is about this. It is the admission of reality. It is not the reaction but the preparation for a situation at the worst, such as those set for cold weather, that it is built upon.

Basic CDL Pre-Trip vs Winter Expanded Pre-Trip

| Inspection Area | Basic CDL Pre-Trip Focus | Winter Expanded Focus |

| Fluids | Presence only | Viscosity, freeze protection |

| Tires | Legal tread depth | Traction performance, pressure loss |

| Brakes | Visual and audible check | Moisture, freeze risk, response delay |

| Lighting | Functionality | Brightness, ice buildup, corrosion |

| Air system | Pressure build-up | Dryer efficiency, moisture drainage |

| Trailer | Basic coupling | Brake lines, ABS wiring, door seals |

Engine Compartment: Cold Weather Is Unforgiving

Engine Fluid and Fluid Levels Check

In winter, checking the engine fluid is not just about presence; it is about the condition and the suitability for the low temperatures. Oil that is acceptable in the fall may cause slow cranking or delayed lubrication during cold starts.

Owner-operators should pay special attention to:

- Engine oil viscosity appropriate for cold starts

- Coolant mixture ratio and freeze protection

- Power steering fluid responsiveness at low temperatures

- Windshield washer fluid rated for subzero conditions

A proper fluid levels check should include a leak visual inspection that may only happen overnight when the temperatures drop. Even a slow-seep can freeze and create pressure-related failures that go unnoticed during a basic inspection.

Rubber bands and Hoses Under Cold Stress

Hoses and belts are the things that show more of the weather in their parts. A belt that is not causing any issues at the time of inspection may fail to work properly after a few cold starts.

In a cold winter check, you should look for:

- Micro cracks at hose fittings

- Soft spots that pop under suction

- Belt glazing or the edge fraying

- Loose clamps that shrink in the cold air

Cold weather examination should always add a hands-on check instead of merely relying on visuals.

Brake System Check: Moisture Makes the Problem

Air Pressure and Moisture Control

Air pressure systems are the most vulnerable components in a commercial vehicle in winter. Accumulated moisture in air tanks and lines can freeze and block airflow.

Owner-operators should:

- Drain the air tanks daily in winter

- Monitor the air pressure that builds-up time after the cold starts

- Listen for the irregular leaks when the seals contract

- Check the air dryer purge cycles

In winter, the brake system inspection should cover the above preparations. Air systems can freeze and either inhibit the brake response or cause a complete failure, which is totally catastrophic for driving on icy surfaces.

Brake Comps Apart from Visual Checks

In winter, brake issues are related to corrosion and are different from the usual just-out-failure cases. Road salt causes the damage brake hardware suffers. In winter, brake problems usually have a pattern of uneven engagement and not free failure.

Owner-operators should look for:

- Rust on drums and rotors

- The frozen calipers that caused uneven pad-wear

- Brake lag after long descents

Winter Brake System Risk Indicators

| Symptom | Possible Winter Cause | Recommended Action |

| Slow brake response | Moisture in air lines | Drain tanks, inspect dryer |

| Pulling during braking | Uneven corrosion | Inspect pads and drums |

| Air pressure delay | Frozen valves | Warm system, service valves |

| ABS warning in cold | Wiring contraction | Inspect connections |

Tires: Networking and Rubber

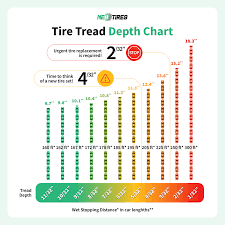

Tire Tread Depth and Cold Performance

Tire tread depth is a part of the equation on playing traction on a vehicle in the winter. Rubber compounds act in a distinct way in the cold, and the worn edges of tires add to the problem of snow evacuation.

An owner-operator’s checklist during the winter season is greatly impacted by:

- Measuring the tread depth at different points

- The inspection of non-standard wear patterns

- The look at the sidewalls for cold-induced cracking

- The air pressure adjustments due to the colder air

The air you breathe is inversely proportional to your body’s functionality. Regardless of the age or size of the tire, changes in air pressure will make it wear unevenly. The most common aging effect of tires is the hypersensitivity to air pressure high or low.

Steering Mechanism: Limited Feedback Equals Less Safety Margin

Steering systems become less responsive in cold weather, thick fluids, and stiff joints. Even a tiny delay can make it difficult to steer on ice.

Watch for these symptoms at winter steering checks:

- Fluid level and flow speed

- Linkage movement under load

- Abnormal noises during cold turns

Steering problems often manifest subtly before they become critical issues.

Lighting Devices: Survival through Visibility

Winter extends the hours of darkness and exposure to snow glare and road sprays. Headlights need to run at peak performance.

Owner-operators should inspect:

- Headlight brightness degradation

- Marker lights for moisture intrusion

- Trailer connectors for corrosion

- Lens clarity after salt exposure

Lighting devices mismatch roadside inspection requirements and compromises the winter safety.

Trailer Inspection: The Lesser-Known Partner

Trailer systems suffer similar winter strain, but they are often inspected much less thoroughly.

An adequate trailer inspection should involve:

- Brake line insulation

- ABS wiring protection

- Door seal and locking rods

- Landing gear lubrication

Trailer neglect is a common reason for the failure of roadside winter inspections.

Post-Trip Inspection: A Winter’s Mark of Damage

Most of the winter-related damage shows only after the shutdown.

A structured post-trip inspection allows operators to:

- Identify ice buildup

- Detect leaks

- Remove salt accumulation

- Prevent overnight freezing

Post-trip checks skipped increasing the chance of the next absorbed defects beginning with the hidden ones.

Pre-Trip vs Post-Trip Winter Focus

| Inspection Phase | Winter Focus |

| Pre-trip | Cold start readiness, moisture control |

| En route | Monitoring brake response, steering feel |

| Post-trip | Leak detection, ice removal, salt exposure |

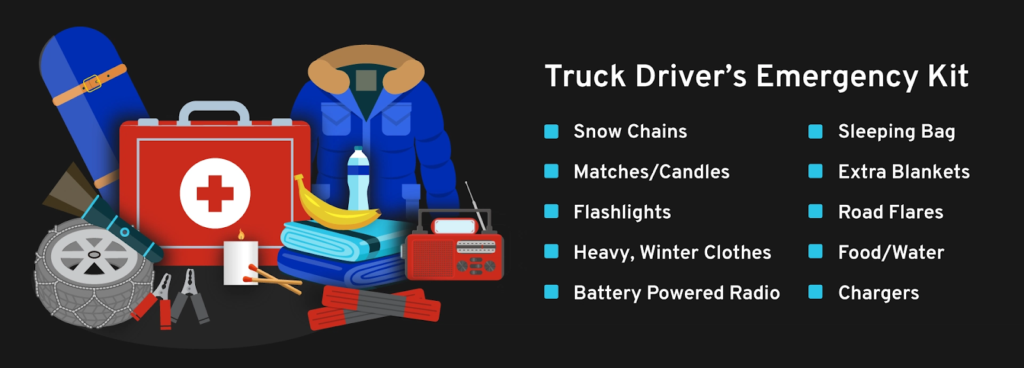

Winter Readiness for Roadside Inspection

The official roadside inspection regulations do not change, but the intensity of observation becomes higher during the winter. Equipment malfunction is a severe risk in icy conditions.

Owner-operators should ensure:

- Emergency equipment is accessible

- Reflective gear is clean and visible

- Documentation is not frozen or damaged

Preparation is where you protect DOT compliance and cut downtimes.

Truck Winterization Is a Process, Not a Product

Truck winterization is not a single act or additive. It is a state of mind that you will always check.

True winterization includes:

- Increased inspection frequency

- Anticipation of freeze-related failures

- Preventive replacement of weak components

A winter-focused commercial vehicle inspection strategy diminishes the risk long before it crops up.

Building an Owner-Operator List for Winter Specifics

A winter checklist should expand and not replace the CDL pre-trip.

Key principles:

- Inspect under cold conditions

- Focus on moisture and corrosion

- Validate performance, not just presence

- Include trailer and post-trip routines

Final Thought: Winter Pre-Trip Is a Risk Management Tool

Winter mishaps not only cost repair money but they also take time and frighten future contracts or safety. The winter pre-trip inspection is more than just the basic program; it is a decision related to business.

Owner-operators that make wider inspections their standard practice see:

- Less roadside inspection issues

- Lower breakdown frequency

- Better winter driving safety

- More consistent operations

Winter catches up with the short runners and relieves the well-prepared. Being disciplined and devoting the day to a pre-trip routine focused on the season is the strongest weapon an owner-operator has to protect the truck and the livelihood.

FAQ — Winter Pre-Trip for Owner-Operators

1. What additional items should a winter pre-trip inspection for an owner-operator checklist contain besides the basic program?

A broader owner-operator checklist needs to highlight systems that react differently to winter climate like fluids, air systems, tires, lighting, and trailer components. The primary objective of a winter pre-trip inspection lies not only in DOT compliance, but also in the early discovery of cold-related risks before the truck is set for use.

2. In what ways does a winter truck inspection differ from a conventional CDL pre-trip inspection?

A winter truck inspection involves more than merely looking at the components it also checks how they work under low temperatures. Cold weather inspection contained an emphasis on moisture control, freeze risk, tractive effort, and system behavior rather than minimum legal requirements.

3. What makes truck winterization a necessity for safe winter driving?

Truck winterization is the procedure for setting up necessary systems for ice-cold operation through the elimination of possible malfunctions due to frozen parts, air pressure loss, or fluid thickening. The correctness of driving on snowy roads highly relies on the preparatory work before the trip and not fixing it on the roadside.

4. Which parts are the most important while performing the winter deep check for the commercial vehicle inspection?

A good winter deep check should concentrate on brake system inspection, fluid levels check, tire tread depth, air pressure stability, belts and hoses condition, and lighting devices. These parts are the most likely to be damaged by temperature drops and humidity.

5. How does the cold weather inspection help the DOT with roadside inspection and readiness?

Cold weather inspection will improve roadside inspection performance by cutting down on visible defects, lighting failures, and brake-related issues. When inspections go beyond basic pre-trip requirements and include a deep winter check, trucks are better prepared for winter conditions. Vehicles that pass these winter-focused checks are less likely to be put out of service during roadside inspection events, directly supporting overall truck safety.

6. Why is trailer inspection attention especially needed in winter operations?

Winter trailer inspection helps confirm that brake lines, ABS wiring, door seals, and coupling components are not compromised by freezing temperatures. As part of a deep winter check, trailer inspection reduces failures that commonly affect winter roadside inspection outcomes. Many seasonal issues arise when inspections do not go beyond basic pre-trip routines, increasing risks to truck safety during winter operations.

7. What benefit does post-trip inspection have to the safety of the winter truck?

Post-trip inspection offers the owner-operator the opportunity to address ice buildup, salt damage, and leaks before they become safety concerns. When post-trip checks are treated as part of a broader deep winter check, they significantly improve truck safety and reduce the risk of cold-start failures at the beginning of the next shift.

8. In what way does the winter pre-trip inspection ensure further longevity of the truck with the help of the owner-operator?

Regular winter pre-trip inspections that go beyond basic pre-trip standards reduce emergency repairs, lower the likelihood of breakdowns, and support smoother operations. A consistent deep winter check strategy is a critical factor in maintaining long-term truck safety, equipment longevity, and business reliability for owner-operators.